Warrnambool's Midfield Meats is undergoing a major makeover worth more than $60 million but the pandemic-hit project will have to use "virtual reality" to make it happen.

Subscribe now for unlimited access.

$0/

(min cost $0)

or signup to continue reading

Work began about three months ago on installing new semi-automated cattle yards, a $30 million storage freezer plant and a protein plant also worth in excess of $30 million.

The new protein plant will supersede the Levys Point rendering plant which will be decommissioned early next year after works at the Strong Street site are completed in February.

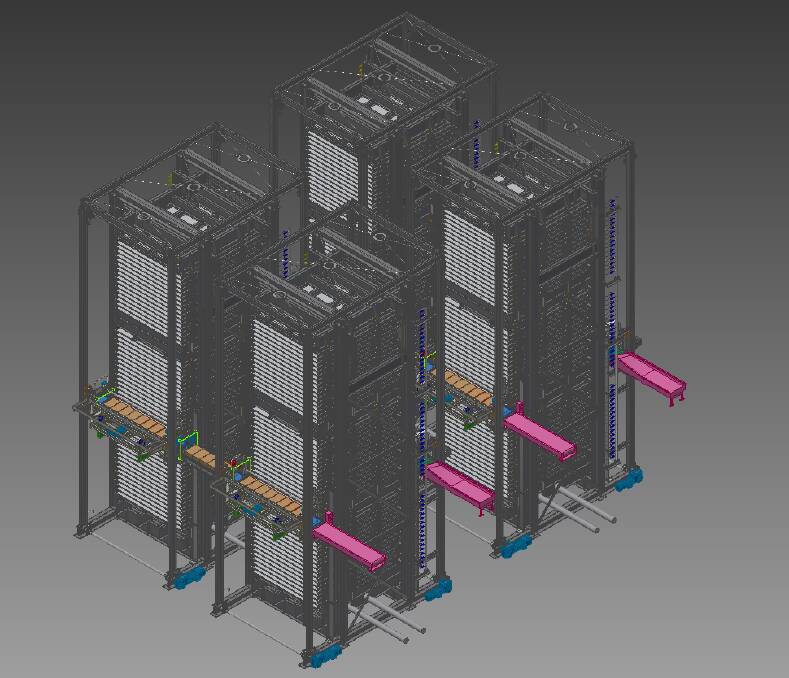

General manager Dean McKenna said 53 containers of specialist machinery from Europe were to arrive onsite over the next three weeks but a ban on international arrivals due to the coronavirus pandemic had meant overseas and Melbourne-based specialists couldn't visit the site to install it.

"It's a little bit challenging to do at the moment because we can't get specialist workers out of Melbourne or from offshore," Mr McKenna said.

"We've had to find alternative means to facilitate that.

"We're going to do a lot of it through virtual reality. They're going to guide us through the process. It's technology coming to the fore."

Mr McKenna said there were about 70 local tradesmen onsite everyday working on the new projects, and some of those would upskill to do the job the specialists were prevented from doing.

He said the company had committed to the works long before the pandemic, and decided to stick with the timeline to ensure it could sustain jobs long-term.

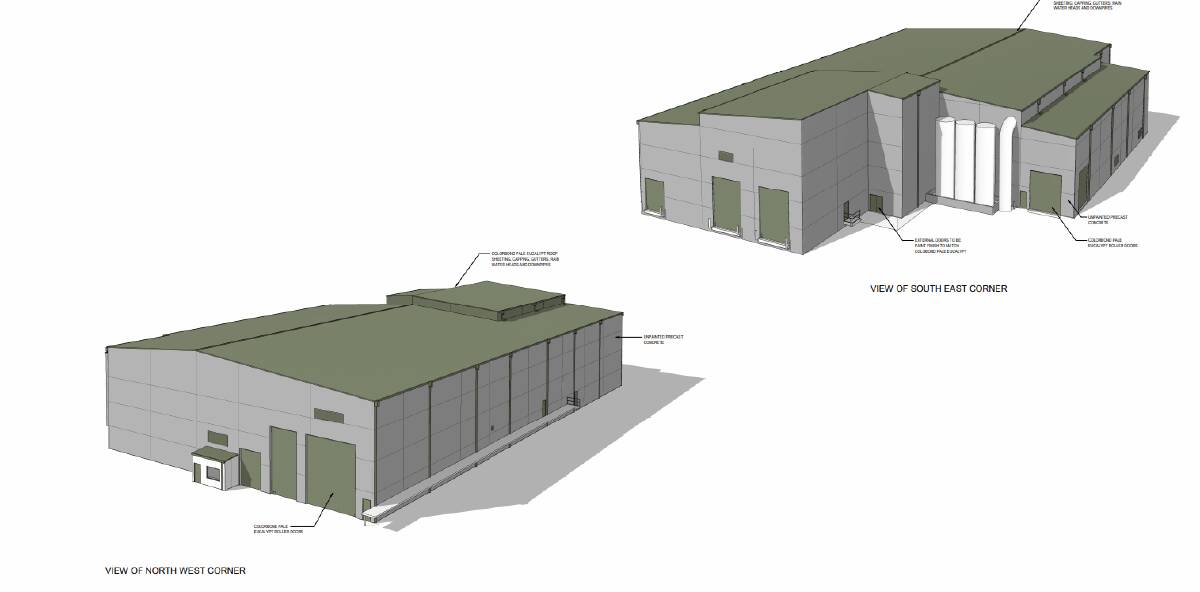

Cranes arrived on site recently to begin work on the most visible part of the revamp - a building which will house 12,000 cartons of meat in a fully automated freezing solution using robotics technology.

Demolition works further along Strong Street have cleared the way for works to begin on the new protein plant.

Mr McKenna said the options for the future of the old rendering plant site near Levys Point were still being explored but it would no longer be an industrial operation.

New semi-automated cattle yards were completed last week and were this week being commissioned.

Mr McKenna said the expansion would allow the facility to be more sustainable and competitive in both the marketplace and at the farm gate while also allowing it to increase production in the future.

"It will result in us having probably the most efficient abattoir in the country," he said.

Production at the factory was scaled back last week after the government forced all Victorian abattoirs to make cuts as the state struggled to get on top of a second wave of the virus.

Mr McKenna said he was hoping production would return to normal when the region's stage three restrictions ended in about four weeks.

He praised the workers for the way they had gone above and beyond government guidelines to ensure a COVID-safe workplace.

"Honestly, I'm like a proud dad. They've been 10 out of 10," he said.

"We're so fortunate we've got the people we've got. No one's pushed back. Everyone's adhered to the guidelines and recommendations. I'd walk around the site and there wouldn't be one person without their mask or PPE gear on correctly."

Our COVID-19 news articles relating to public health and safety are free for anyone to access. However, we depend on subscription revenue to support our journalism. If you are able, please subscribe here. If you are already a subscriber, thank you for your support.